Electrical resistivity imaging (ERI) surveys inject current into the ground between two electrodes to measure the voltage difference between two other electrodes to produce 2D electrical images depicting detailed variations in subsurface electrical properties. ERI survey arrays are typically completed from the ground surface, or between boreholes for higher-resolution deep resistivity mapping. Each electrical image can depict both lateral and vertical extents of a target. For multiple profiles, data can be processed in 3D to produce sliceable, rotatable block images. ERI is used to map features like clay layers, sand and gravel lenses, leachate plumes, dam seepage, water-bearing fractures, mines and caves, mineralized zones, disposal pits, and more.

Case Study: Not Your Ordinary Layer Cake

RETTEW worked with a client to determine the depth of a suspected clay layer beneath the client’s site so a suitable remediation plan could be designed. The clay was overlain by a series of sand and gravel layers, which created a good physical contrast between them and the underlying target. So, RETTEW conducted an ERI survey to map the electrical contrast between the resistive sand and gravel layers and the deeper, more conductive clay.

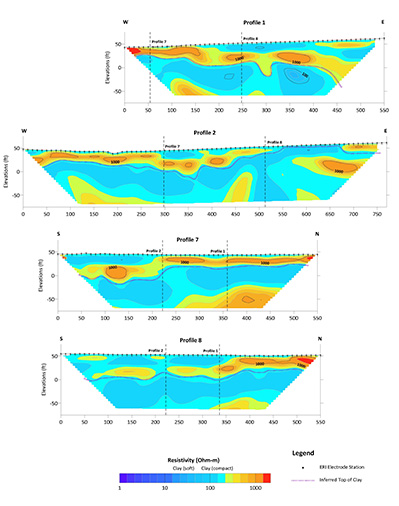

The four cross sections, laid out in a tic-tac-toe pattern across one area of the site, depict the relatively thin, shallow sand and gravel layers (orange to red, high resistivity or low conductivity) overlying the deeper, thicker clay layer (shades of blue, low resistivity or high conductivity). A short hachure line marks the assumed approximate boundary between these two electrically distinct features. Minimum clay layer thicknesses were estimated from each of the cross sections.

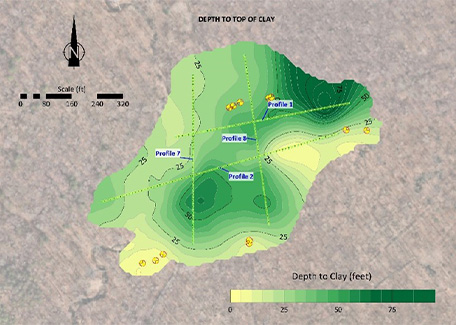

Data from the cross sections were then used to create a contour map showing the depth to the top of the clay layer across the site. This enabled our client to design a suitable remediation plan knowing the “topography” of the buried clay layer across the site. The cost of the ERI survey was offset by the reduced number of borings our client would have installed to “ping” the top of the clay layer intrusively.

Meet Sarah Powanda

Project Technician

Meet Sarah Powanda, an adventurous project technician who is passionate about learning, exploring new cultures, and expressing herself through fashion and art. Go “beneath the surface” in our employee spotlight and get to know Sarah!