Building renovations and repairs often involve drilling holes in floors, walls, or ceilings. To preserve safety and structural integrity, it’s essential to position holes to avoid reinforcing bars (rebar), electrical, alarm/signal cables, and post-tensioning (PT) cables.

RETTEW provides corehole clearance using state-of-the-art magnetic, electromagnetic (EM), sonic/acoustic, ground penetrating radar (GPR), and live-line detector techniques to detect and mark electric conduits, rebar, PT, fire alarm wires, and other obstructions in the vicinity of proposed drilling or coreholes. Concrete scanning can also detect voids in concrete and masonry structures (e.g., ungrouted cells in cinder blocks or bridged voids in poured concrete).

In Search Of…Rebar, Grout, and Voids

A new auto dealership was under construction when the coronavirus pandemic hit. Supply-chain issues, coupled with a shortage of subcontractors to complete the building’s framework, meant the general contractor had to rely on untested subcontractors to complete the work.

While the subcontractor crews worked to complete the building without additional delays, the general contractor noticed the concrete block was cracking above a large garage door, and the lintel above the opening was starting to bow. Immediately, the contractor suspected there was something wrong with the wall construction. Although the general contractor believed the subcontractors had conducted project oversight while constructing the wall, no one could provide documentation confirming the walls were built to specification.

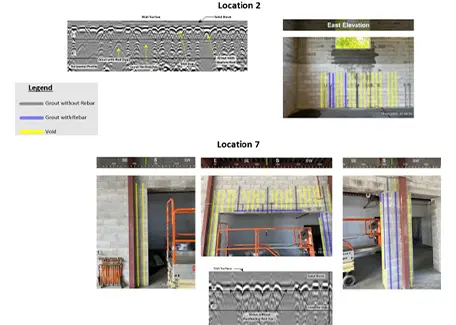

Recognizing the need to determine the root cause of the cracking and bowing issues, the client contacted RETTEW to conduct concrete scanning of the cinder block walls with GPR. Nine locations showing distress were scanned to detect the presence of reinforcing rods (rebar) and grout, and to see whether there were voids in the grout. Images from the scanning identified the columns with the specified grout and rebar (blue), columns with voids or places where grout was missing (yellow), and columns with grout but no rebar (gray). Clearly, someone had cut corners to save time and money!

As a result of these initial findings, RETTEW scanned every inch of all load-bearing walls to thoroughly document potential problem areas. By identifying all of the compromised columns, the client was able to ensure each one was repaired to the owner’s satisfaction before the dealership opened.

Meet Bill Steinhart

Senior Geophysicist

Bill enjoys the challenge of using instruments to locate things most people never see. However, occasionally, doing so can be the challenge. Go “beneath the surface” to find out more and get to know Bill in our employee spotlight!